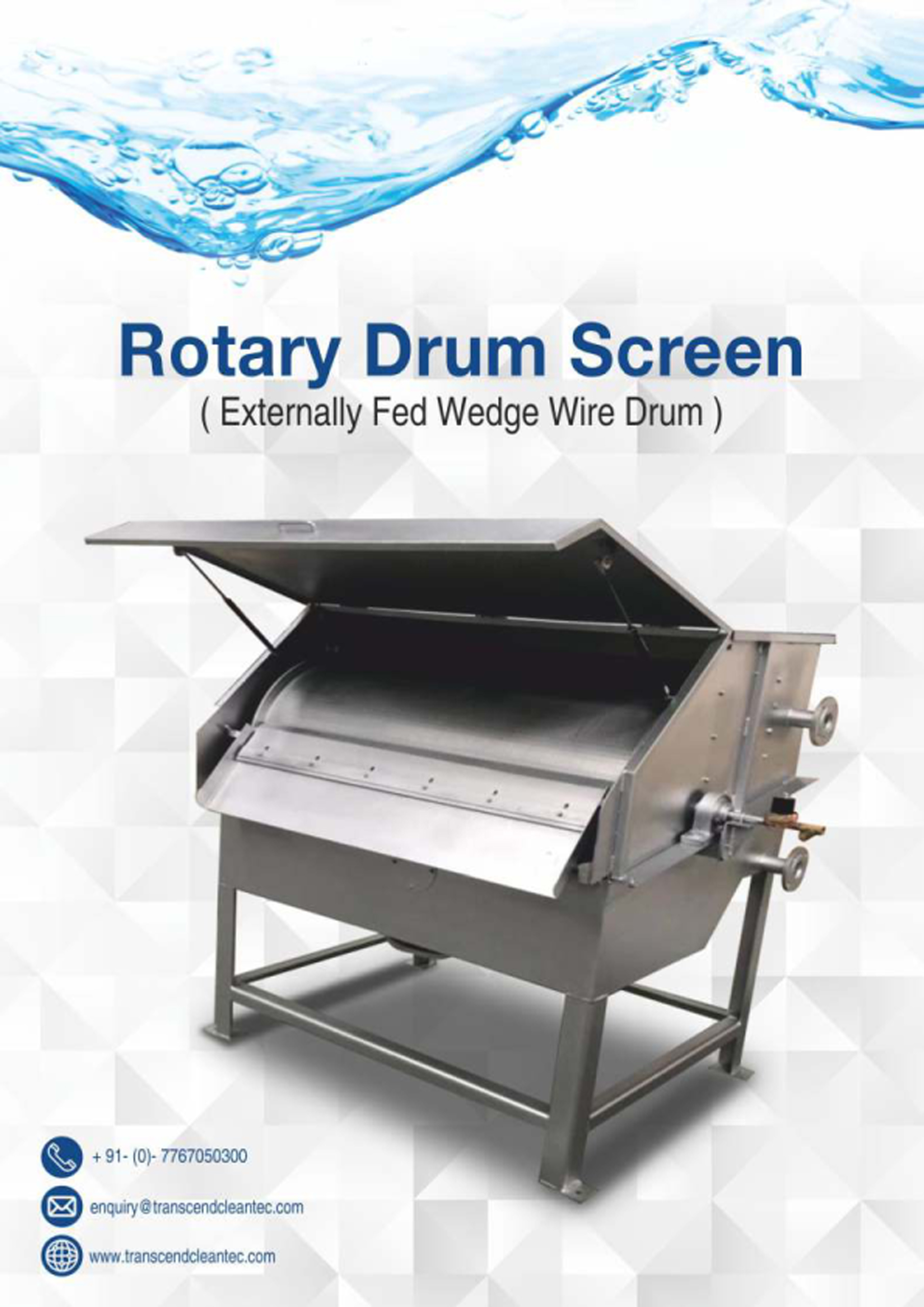

Drum Screen

Rotary Drum Screen design-focused filtration solutions. The rotary drum screens are applied for separating solids from process and wastewater. Drum screen are suitable for a variety of applications from raw sewage to ultra-fine screening of water and wastewater membrane treatment systems. Rotary Drum Screen Filter has a higher load capacity and maintains a long service life. The drum screen is one of the most demanded types of equipment for the mechanical treatment of industrial and domestic wastewater. We are engaged in offering a qualitative range of Rotary Drum Screen to our customers. We have constructed a wide and well functional infrastructural unit that plays an important role in the growth of our company. We offer these products at reasonable rates and deliver these within the promised time frame.

When installed in a channel of the pumping station, the rotary screen traps suspended solids by Wedge Wire Screen. The solids collected at the top of the inside of the screen are flushed out with flushing water down into a discharge trough for collection. It has been used in a variety of food & beverage and industrial wastewater applications including Sugar, poultry, and seafood, fruit and vegetable processing, pulp & paper production. The solids collected at the top of the inside of the screen are flushed out with flushing water down into a discharge trough for collection. It has been used in a variety of food & beverage and industrial wastewater applications including Sugar, poultry, and seafood, fruit and vegetable processing, pulp & paper production.

Features:

- Large flows possible

- Removes solids efficiently

- Prevents blinding or clogging of the screen

- Variable-speed drum rotation maximizes effectiveness also possible

- Full-length water knife dislodges trapped solids

- Drum is the only moving part, reducing cost maintenance

- New self–cleaning arrangement

- Reduced floor space requirements

- Low headroom requirements

- Fewer moving parts

- Variable speed drive also possible

- Automatic backwash also possible

- Low initial investment

- Baffle flow plate director

- Available in wedge-wire, perforated, and mesh screen types.